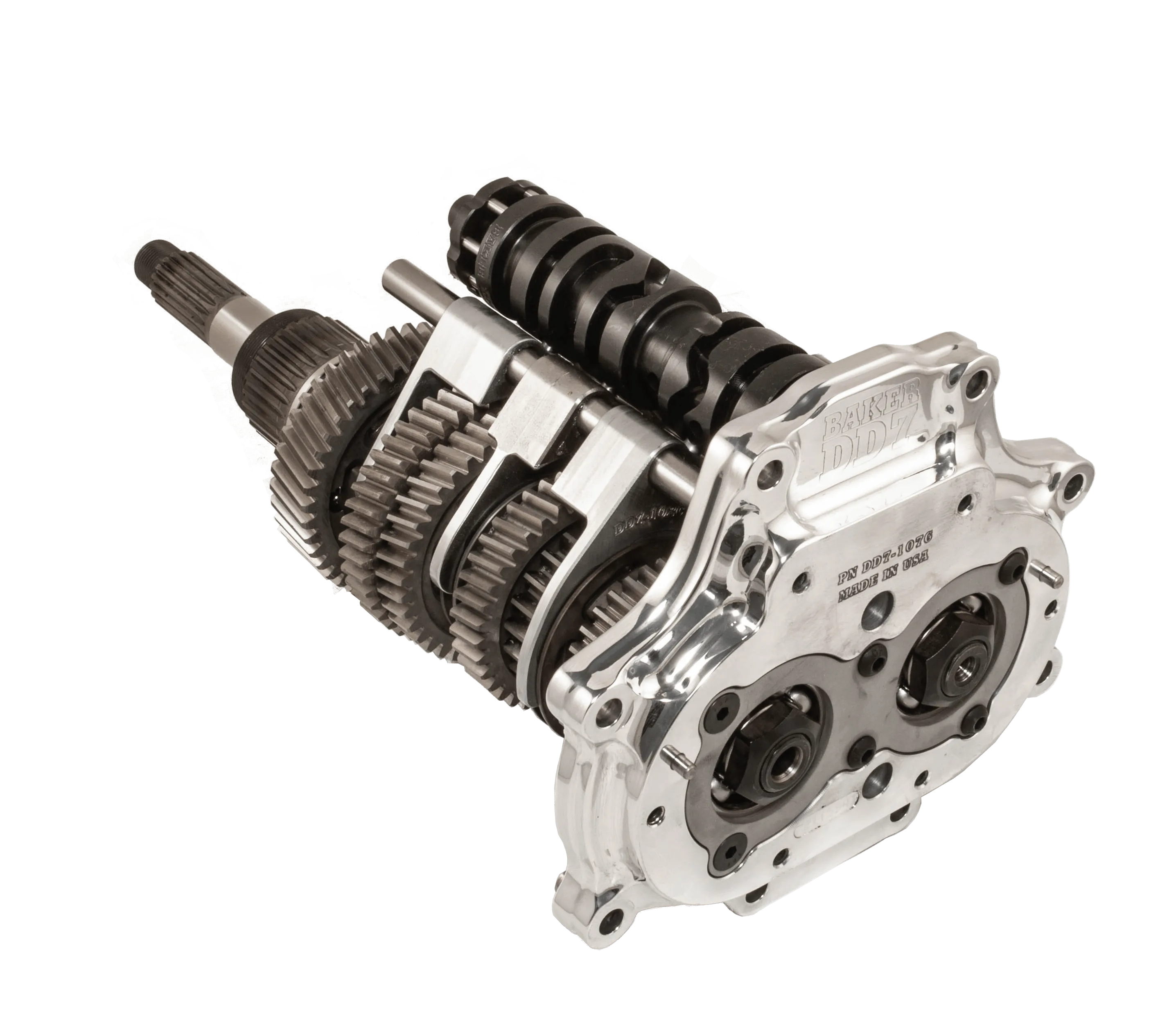

We did not stop at just fixing the gear ratios. We improved the smoothness and crispness of the shifting by reducing the mainshaft mass by only having 1st gear be a part of the shaft, rather than 1st-4th gears like on the stock unit. Reduction in rotating mass for shift quality is a fact that has been utilized in the automotive world for years. We ditched the stock detent arm and spring assembly from the door in favor of a Linear Detent that decreased friction while increasing smoothness when coupled with the all new shift drum design. We have tightened up the dog teeth on the gears to prevent the loud clacking noise that accompanies every shift on the factory 6 speed. Through the use of a billet bearing door, 28% wider bearings in the door, steel bearing retainer plates and full width gears, the durability and strength of our unit is a drastic improvement. By utilizing fully diamond ground, helical gears in 1st & 4th-7th we are able to deliver a much quieter riding experience. While 2nd and 3rd gears are diamond ground, spur gears to handle the peak torque that is reached in that range.

NOTE: To upgrade your older DD7 to the new Tapered Bearing style main drive gear bearing you must purchase PN 740-67. The current kit comes standard with the Tapered Bearing Kit.

Features

- Shorter first gear ratio (numerically higher) to help with the off the light get up and go, as well as slow speed maneuvering around the bar parking lot

- Fully assembled gear set and shift system. No adjustments needed for installation

- The DD7 includes a BAKER shifter pawl, new main drive gear bearing and seal, door, top and side cover gaskets

- Compatible will all types of aftermarket hydraulic side covers, as well as the stock Screamin Eagle versions

- Typically no clearance is required. The DD7 is designed to fit in OEM case. On occasion, the case may require clearance due to OEM fluctuations in the case-casting process

- Clears all exhaust and works with all aftermarkets clutches

- Included BAKER Direct Drive 7 Speed Stock Side Cover emblem

- Backed by a 5 year limited warranty

Benefits

- Make full use of the late-model torque and power output

- Experience of smooth, crisp, continuously pulling acceleration

- No big drops in RPM from one gear to the next

- No lugging the motorcycle off of a stop light

- Easy to find neutral, every time

- Smooth shifting without the the stock clunks or ‘jerks’ when engaging

- Stronger torque capacity

- Quieter

Fitment

- 2007-later Softail

- 2007-later Touring: FL, FLT, FLH*

- 2006-later Dyna

*Does not fit 2023 and later CVO models.

Optional Cruise Drive Pulleys: Along with the launch of the Cruise Drive transmission on the 2006 Dyna models, the factory started using bigger diameter splines on the output gear. This change made us tool up a new pulley to meet the tuning needs of our performance-minded customers.

Re-flash ECM: The DD7 has different gear ratios than the stock transmission (except DD7 7th gear is the same as stock 6th gear, 1:1). This changes the input to the ECM. The gear indicator and cruise control may only operate in 7th gear. To correct the gear indicator in all gears and enable cruise control, an ECM re-flash is required. Existing tuners must have an option to modify transmission gear ratios in order to re-flash the ECM.

BAKER Drivetrain offers re-flash values for Powervision, ThunderMax, TTS, and Techno Research tuners. Click here for the DD7 Recalibration Values

Part Numbers

| DD7-M802 | DD7 Builder's Kit, M8 Models, Polished Door (Except 2023-2025 CVO, 2024-2025 Street Glide, 2024-2025 Road Glide and 2025 Softail) |

| DD7-M803 | DD7 Builder's Kit, M8 Models, Black Door (Except 2023-2025 CVO, 2024-2025 Street Glide, 2024-2025 Road Glide and 2025 Softail) |

| DD7-M8022 | DD7 Builder's Kit, M8 Models, CVO Charcoal Door (Except 2023-2025 CVO, 2024-2025 Street Glide, 2024-2025 Road Glide and 2025 Softail) |

| DD7-37602 | DD7 Builder's Kit, 2006-2017 Dyna, 2007-2017 Softail, 2007-2016 Touring, Polished Door |

| DD7-37603 | DD7 Builder's Kit, 2006-2017 Dyna, 2007-2017 Softail, 2007-2016 Touring, Black Door |

Detail

Shift System

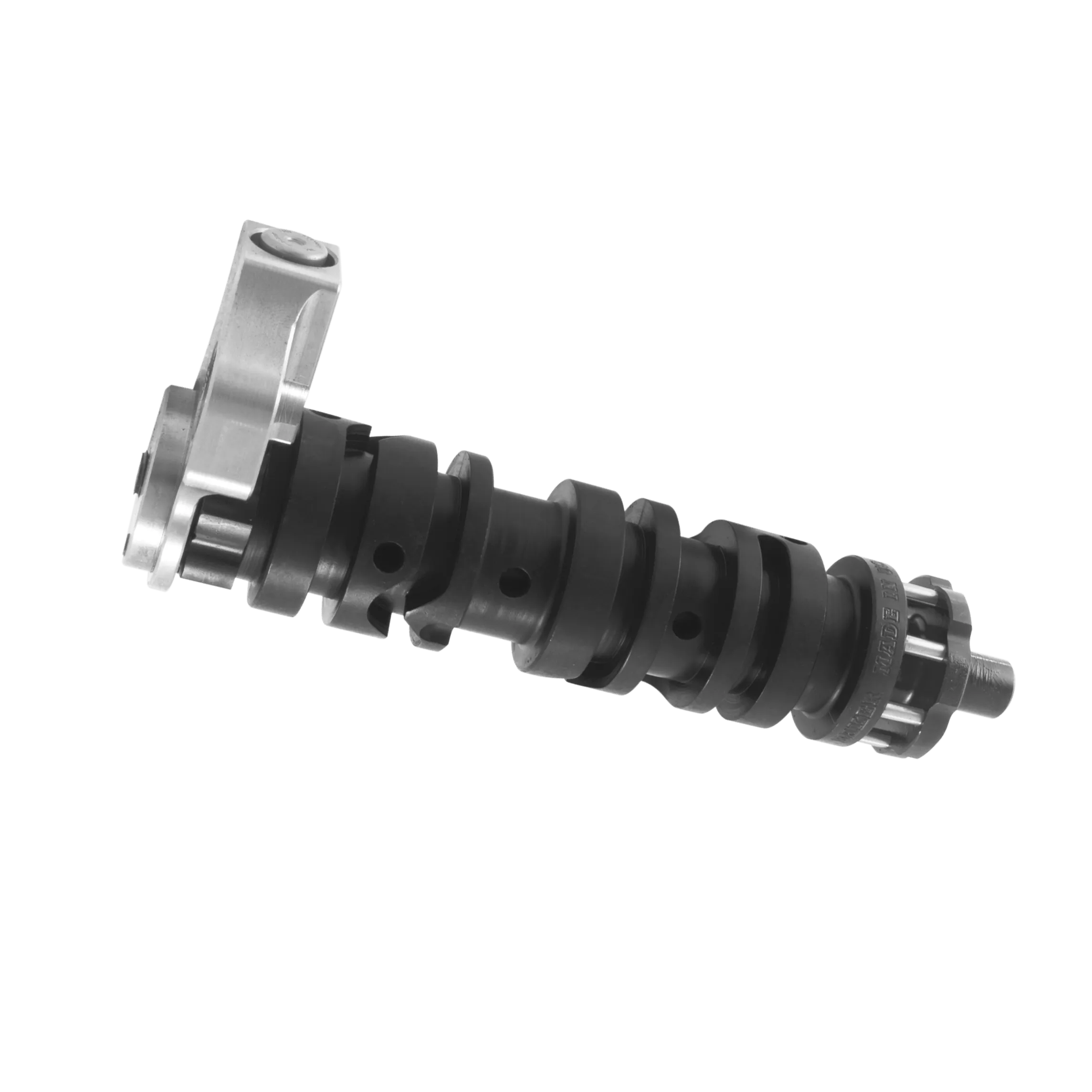

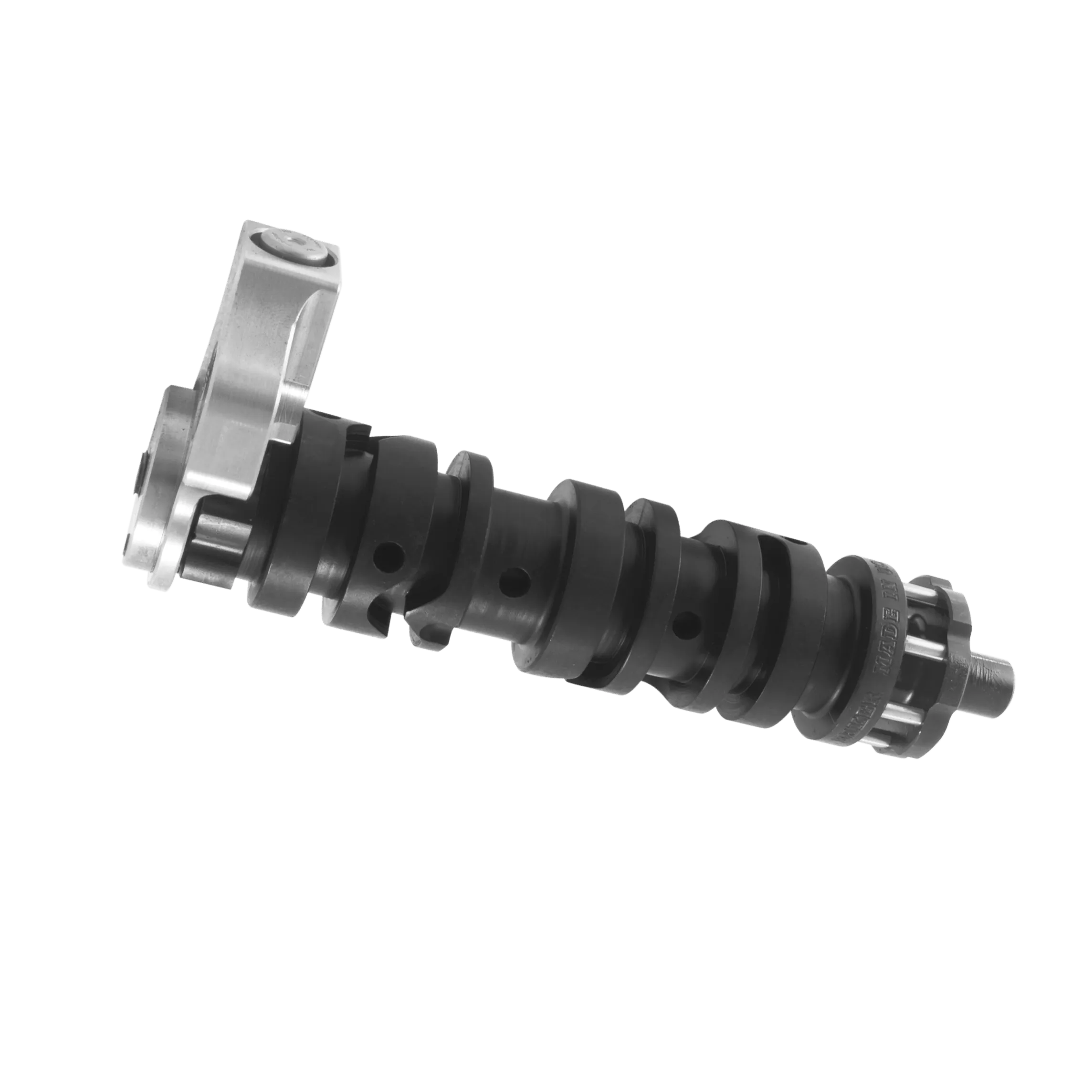

The shift drum utilizes many of the same features we have learned over the years, and incorporated into our other designs. Make the shift drum as light as possible, close tolerance design of the drum tracks matched with specific angles of the drum tracks ‘events'; make for smooth and positive shifting. Our specifically designed neutral position on the shift drum detent clover leaf make it easy to find neutral, every time. The close tolerance drum design paired with the gearset lay out, yields tight, repeatable dog tooth gaps that are not possible with mass production, cast shift drum designs used on the stock transmission.The linear detent, a design first used in the OEM car world. We were the first to introduce it to the V-Twin world on the Torque Box transmissions, and we have used it on the DD7 as well. It produces the lowest friction possible, with the controlled nature of using a coil spring in a strictly linear manner. The amount of precise control possible with a linear detent, can not be realized with the stock scissor spring and lever wheel detent design found on the stock gearset. All of these changes along with the billet steel machined, hard chrome plated shift forks, make it the smoothest transmission we have made to date.

DD7 vs Stock Shift Drum |

Linear Detent Plunger |

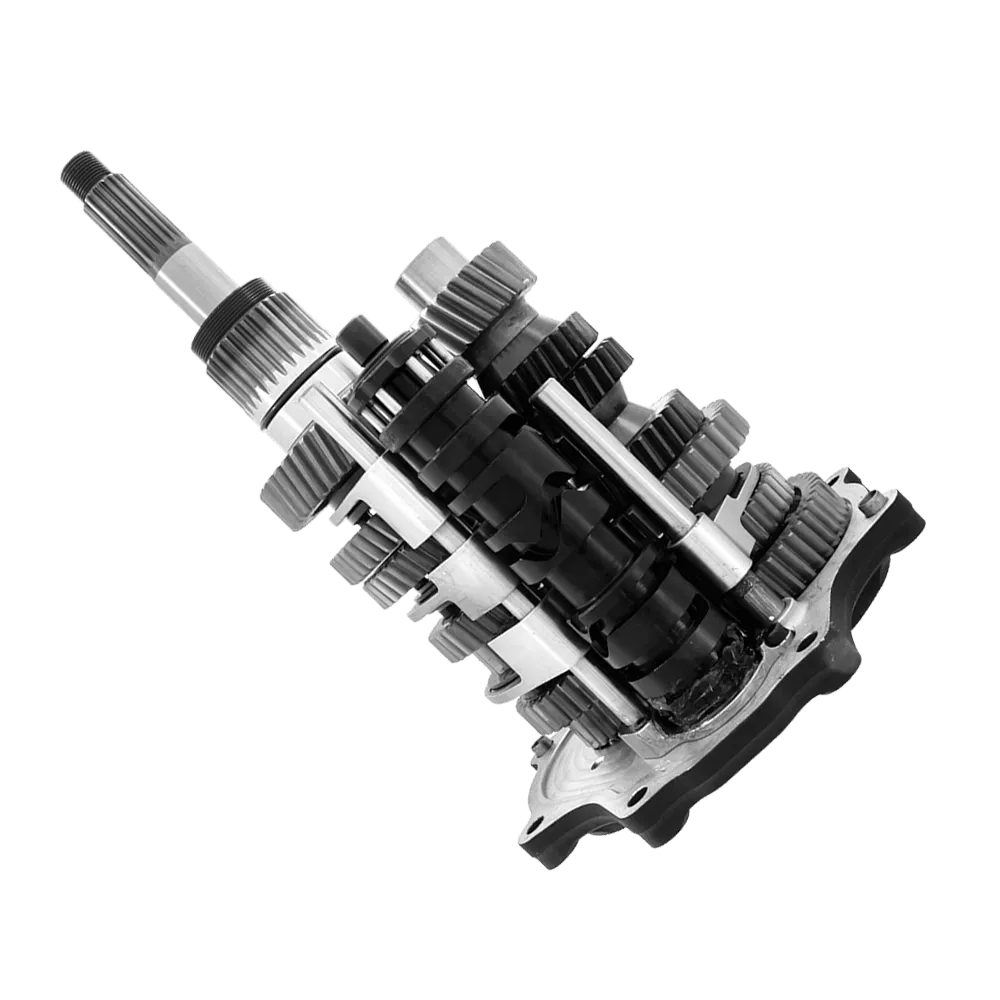

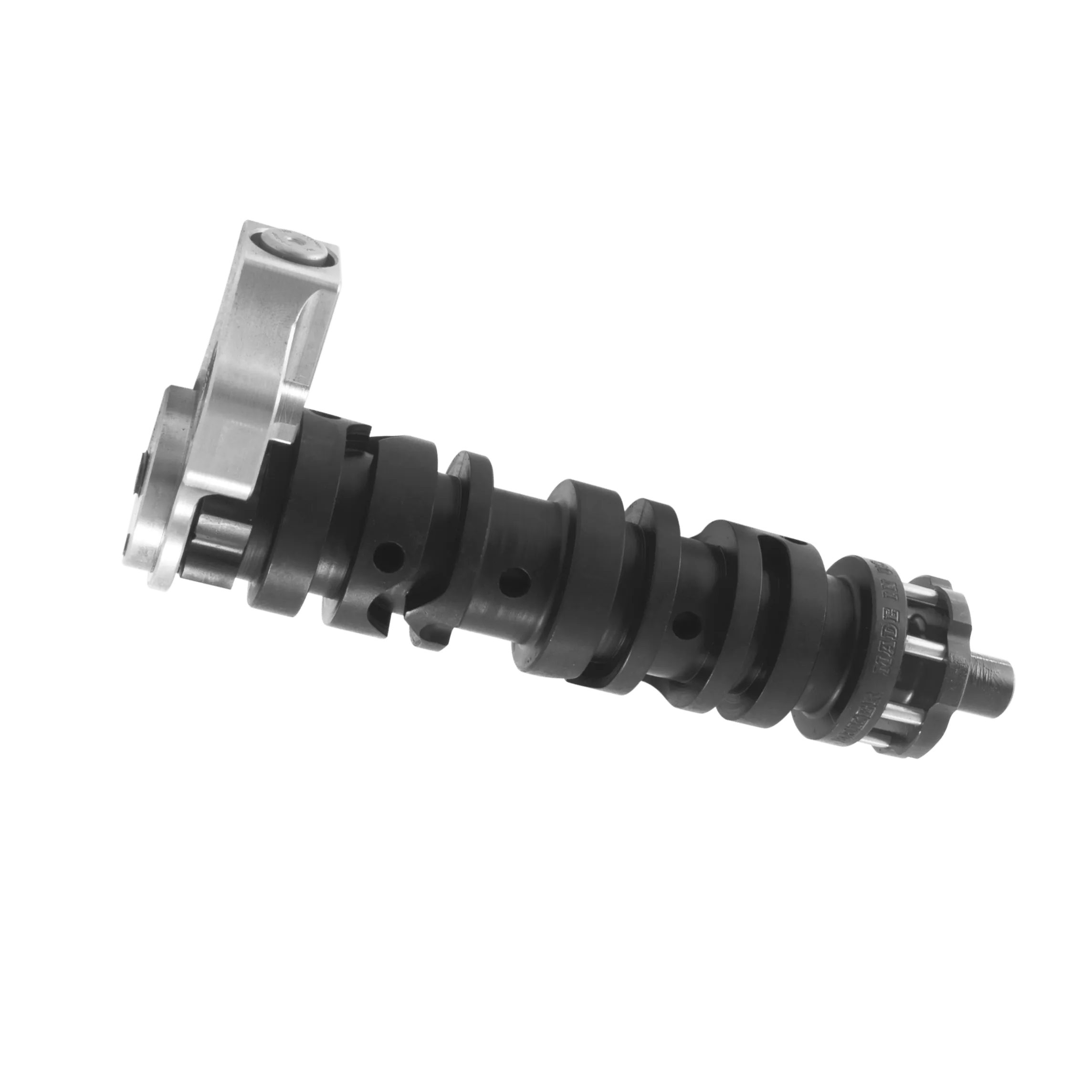

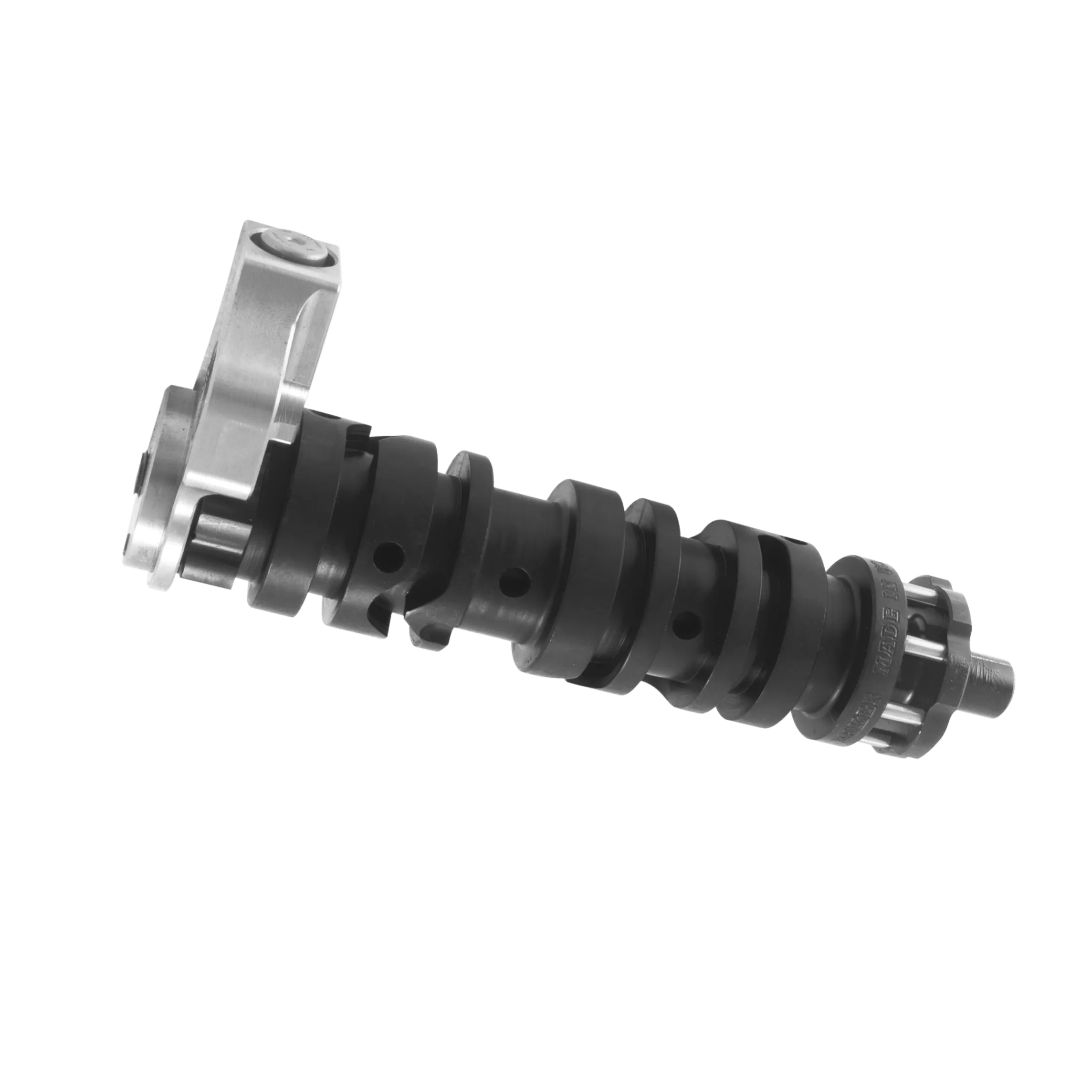

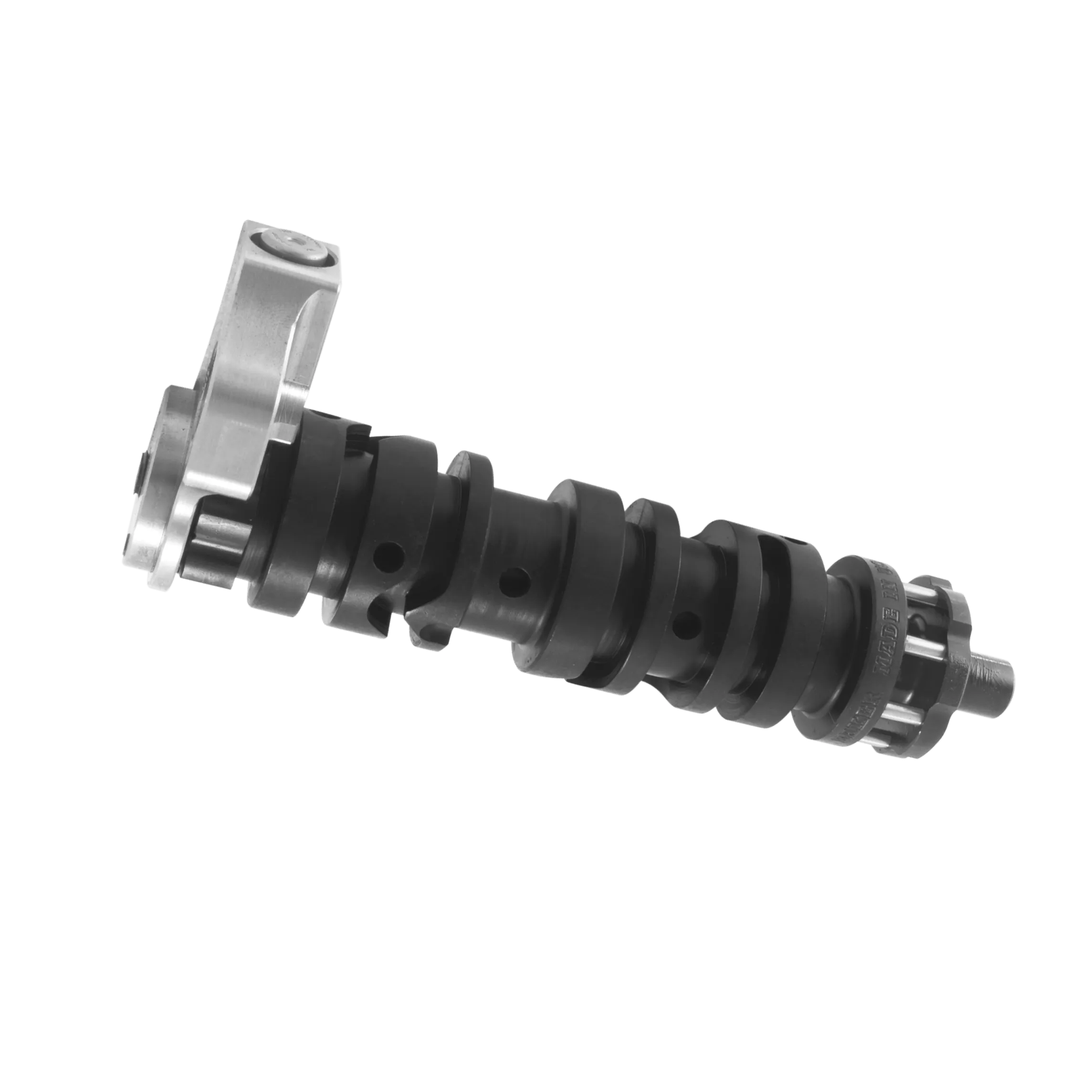

Gearset

The factory 6 speed has a 1 piece mainshaft with gears 1-4 machined out of one forging. This is easier and cheaper for high volume manufacturing, but yields a mainshaft that weighs over 5 lbs. This heavy one piece design is largely responsible for the clunk heard on every shift. This heavy rotating mass crashes into the gears on every shift. The DD7 has a 1 piece mainshaft (8620 steel) that only incorporates the small diameter 1st gear and weighs 3 lbs less than the stock unit. Whereas the stock gearsets utilizes a straight cut gear for 1st, and helical for 2-6, the DD7 uses straight cut 2 and 3rd gears, with the remainder being of a helical design. The largest amount of torque is put to the ground in 2nd 3rd gear, and straight cut gears handle that power the best. There is a not a lot of cruising going on in these gears, so the strength benefit of straight cut teeth outweighs the noise reduction factor inherent with a helical tooth design. The stock gears have tooth profiles that are cut on a shaper machine after heat treat, the BAKER gears are shaper cut before heat treat then precision ground with diamond coated tooling after heat treat (58-62 Rockwell ‘C’). This extra steps ensures not only a quieter gear pair, but enables much tighter backlash control. Further enhancements have been made to the male-female dog tooth pocket interactions, the tightened up radial gap on our design reduces the on-off throttle lag time and gear clunk noise found on the stock transmission.

DD7 Gears vs Stock |

| DD7 | Ratio | Stock | Ratio |

| 1st Gear | 3.76 | 1st Gear | 3.34 |

| 2nd Gear | 2.75 | 2nd Gear | 2.30 |

| 3rd Gear | 2.06 | 3rd Gear | 1.71 |

| 4th Gear | 1.55 | 4th Gear | 1.41 |

| 5th Gear | 1.27 | 5th Gear | 1.18 |

| 6th Gear | 1.10 | 6th Gear | 1.00 |

| 7th Gear | 1.00 | 7th Gear | N/A |

Bearing Door Assembly

The stock bearing door is cast aluminum, the DD7 door is machined from virgin billet 6061-T6 aluminum. Billet is stronger and this instance is no different. The stock gearset’s cause a phenomenon we call ‘Ghost Lever’. Starting from low RPM’s in 2nd or 3rd gear go right to WOT and then get off the throttle. Watch the clutch lever walk in and out from the handlebar. This is the shafts in the transmission walking left and right in the case due to the flex of the bearing door and the skinny stock door bearings. We use 28% wider roller bearings in the door and used a cold rolled 1045 steel plate to hold them in place, rather than the stock snap rings. No more Ghost Lever and much more power (up to 160 ft-lbs) can be thrown at it without the bearings breaking a sweat.

DD7 vs Stock Door |

DD7 vs Stock HD Door Assembly, Section View |

Fitment Note: Cruise Control will only work in 7th gear and the Red Line will be 5200 RPM with the DD7 on Throttle-By-Wire bikes equipped with stock ECM’s. No other motorcycle functions are affected in these instances. The 6th gear indicator light will come on when the DD7 is shifted into 7th on all models and all ECM’s. Aftermarket tuners such as ThunderMax, Daytona Twin Tec, and TTS-Mastertune will allow cruise to function in all gears, like stock, on Throttle-By-Wire bikes when coupled with the DD7 gearset. Dynojet can also flash your stock ECM to adjust the cruise control the cruise and red line, while still allowing the ECM to work with piggy back units like Power Commander. Any questions on this, please give our tech line a call.

Recommended Fluid Level

Picking the right transmission fluid ensures the life and durability of your transmission, that’s why BAKER recommends a fully synthetic GL-5 rated gear weight oil of 75W-140. If a GL-5 rated gear lube is not available, these commonly carried viscosities (weights) will work 75W-90, 75W-140 and 85W-140. BAKER does not recommend the use of Syn3 (20W-50). For Bert’s article on ‘Oil & Spiders’ Click Here

- BAKER DD7 Fluid Capacity Dry: 30-32fl-oz

- BAKER DD7 Fluid Capacity Wet: 26-28fl-oz

Learn more about Spectro Performance Oils here:

Installation Instructions

- BAKER DD7 Installation Instructions: Click Here

- BAKER DD7 Gearset Exploded Views : Click Here

- DD7 Recalibration Values: Click Here